Program Schedule

Site Visit

Wednesday, 10 April, 2024

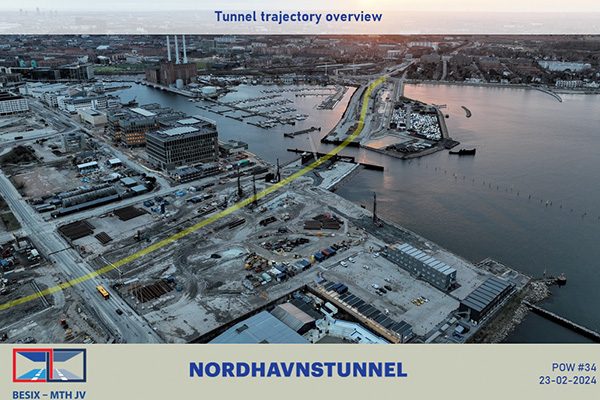

Nordhavn Tunnel Project (BESIX - MT Højgaard Denmark)

| Time | Activity |

|---|---|

| 1400 | Meeting point Tivoli Congress Center & transport to the construction site |

| 14:30 | Presentation of the project |

| 15:30 | Site Visit |

| 17:00 | Coffee & talk, transport to Tivoli Congress Center |

| 18:00 | Return to Tivoli Congress Center |

Thursday, 11 April, 2024

| Time | Title and Speaker |

|---|---|

| 9:00 - 9:30 | Registration |

| 9:30 - 9:45 | Opening Jakob Hausgaard Lyngs, President Danish Geotechnical Society & Maurice Bottiau, President DFI Europe |

| 9:45 - 10:25 | Keeping the geotechnical triangle in balance. Lessons learnt from

failures. Tony O’Brien, Mott MacDonald |

|

Geotechnics involves a number of interlinked activities from

initial

desk studies/investigations through characterisation/analysis

and,

importantly, linking design to construction means and methods.

This

complex interplay between different skills and activities can be

succinctly summarised by ‘The Geotechnics Triangle (i)’. Success

requires the Geotechnics Triangle to be kept in balance. Lack of

attention or skills in any part of the Triangle often leads to

failure. Effective communication between specialists and

non-specialists also plays a pivotal role. This presentation

will

traverse across the Triangle, from initial studies through to

foundation construction, and give mini case history examples of

how

projects failed when key aspects in the Triangle were not given

proper attention. A feature of Geotechnics failures is that they

can

be ‘Black Swan’ events (ie have disproportionate consequences

well

beyond any project risk contingencies) – this needs to be better

recognised by the wider industry. Some suggestions will be

offered

about how we can reduce risks and rise to future challenges. |

|

| 10:25 - 11:05 | Masthuggskajen, where the soft clay and strict design requirements

are quite a challenge. Jonas Ostersen, Aarsleff |

|

In central Gothenburg at Masthuggskajen, a peninsular in the Göta

River is currently under construction. The peninsular consists

of three construction pits enclosed by a pile deck. The soil

conditions are predominated by Gothenburg clay, a soft

normal-consolidated clay which is well-known to cause stability

issues and movement to nearby structures when conducting

soil-related construction. |

|

| 11:05 - 11:25 | Coffee break, visit exhibition |

| 11:25 - 12:05 | Structural bearing capacity of piles in loose soils – a view from

Sweden, with glances at other Nordic countries and the new

Eurocode. Peter Alheid, Hercules |

|

Buckling of piles has been an issue for a long time in Sweden and

most of the Nordic countries due to the very loose clays of

Scandinavia and Finland, in connection with the historic use of

slender piles of both concrete and steel. This has made

structural

bearing capacity equally important to geotechnical bearing

capacity.

Since the -70s and the works of Bernander/Svensk, analytical

calculations of pile buckling in clay and loose soils, taking

second

order effects into account, have been in use. This leads to

focusing

on bed modulus and implicitly, shear strength in clay. What

means do

we have to find the “right” values? Calculations are not only

made

in ULS, but also in SLS, following EN 1992 and 1993

respectively,

but also not allowing yield in the soil. A single focus on

geotechnical bearing capacity in those circumstances can,

however

rare, lead to the collapsing of the superstructure. An example

is

presented. |

|

| 12:05 - 12:45 | Test or suffer the consequences. Jørgen Steenfelt, Cowi |

|

For large scale or important infrastructure projects wind tunnel testing, concrete testing etc. are a given. However, for the most important part, the foundations, testing is routinely dismissed as being too costly or not needed! The only exception is ground anchors where testing is codified. Testing of foundation piles should be mandatory to avoid failures and allow for optimization (cost saving), robustness and ease of construction. The lecture provides examples of the benefits of testing combined with timely and sufficient ground investigations as a basis for piling foundations. |

|

| 12:45 - 13:50 | Lunch, visit exhibition |

| 13:50 - 14:30 | Flaws and adversities in standard pile construction and how they

affect pile performance. Maurice Bottiau, Franki Foundations Belgium & Gilliam de Nijs, BMNED |

|

As the authors have been highlighting in previous papers, many

parameters play a role in the final pile performance, from

adequate soil investigation to performance monitoring and

testing. The correct understanding of pile construction, though,

remains crucial. During construction, some unexpected behaviour

can occur, and the soil reaction to pile installation can

sometimes be completely different than anticipated.

The authors propose to review several issues affecting the daily

practice of pile construction, such as bleeding, overflighting,

necking of displacement piles, etc…on which they have been

performing decades of analysis and research, in order to try to

give some guidance. |

|

| 14:30 - 15:10 | Importance of designer’s on-site presence during development and

execution phase. Håkan Eriksson, GeoMind |

|

Two projects are presented, one that rendered in lots of extra

costs and delays and another a success project. The outcome from

both projects were strongly dependent on the relationship and

interaction between the client and contractor. The on-site

development and refinement of the design helped to a great

extent to strengthen the confidence between designer, contractor

and client. |

|

| 15:10 - 15:30 | Coffee break, visit exhibition |

| 15:30 - 16:10 | A Review of 24 Projects across 4 Continents over the last 20

years. Chris Harnan, Ceecom Consult Ltd |

|

The presentation will review a diverse range of projects across 4

continents, chosen amongst the many the author has been working

on for more than 45 years in the UK and overseas as both a Deep

Foundations contractor and consultant, geotechnical advisor to

clients, main contractors and insurers, and Expert Witness on

several Arbitrations. An assessment of the driving factors

leading to problems on each project will be given. This

assessment identifies the common main factors as those relating

to design, workmanship, lack of coordination between the

parties, inexperienced designer or contractor, and unforeseen

ground conditions. |

|

| 16:10 - 16:50 | Breaking with the past. A new contractual approach to complex

infrastructure projects. Dirk Bennje, Hamburg Port Authority (AöR) |

|

The Port of Hamburg is Germany´s largest seaport. Its main

infrastructure is maintained by and operated at the

responsibility of Hamburg Port Authority (HPA), public-law

institution, which was established in 2005 as part of the

merging of various Hamburg authorities with port-related duties.

This responsibility puts HPA in the role of a contracting

authority that manages a project volume of several hundred

million Euros per year. The contracts awarded cover design and

construction works of all kinds of civil engineering projects

within the Port of Hamburg. |

|

| 16:50 - 17:20 | Panel discussion Moderator : Gunilla Franzén, GeoVerkstan |

| 17:20 - 17:30 | Conclusion Maurice Bottiau, President DFI Europe & Jakob Hausgaard Lyngs, President Danish Geotechnical Society |

| 17:30 - 18:30 | Networking drink |

| 18:30 - 20:30 | Dinner at the Restaurant Gemini |

Order of the presentations subject to changes.